A Word About Wood

In 2002 Hurley Byrd opened the doors crafting feeders from the finest cedar available.

Then in 2013 we added a new lumber, a high grade Preserved Wood Lumber (PWL).

Now for the 2019/20 Season..... we're introducing a new program exclusive to Hurley Byrd.

We call it Forest 2 Finish 2 You. (FFY for short) Read on..........

Archived History: 2002 Western Red Cedar

Western Redcedar (Thuja Plicata)

Is indigenous to the Pacific Northwest United States, north through

Western Canada and into Alaska. It is harvested under strict sustainable

forestry practices with extreme guidelines to prevent deforestation.

Longevity and Weather Resistance

All cedar is naturally decay resistant due to its high oil and

resin content as it wards off the effects of rain, humidity and the sun's

UV rays. Cedars also possess very high levels of tannin which act as a

natural insect repellant. But, the species Western Redcedar itself is far

superior for outdoor use as it's oil and tannin levels far exceed

those of Inland, Eastern and other cedar species.

This is why Hurley-Byrd uses Western Redcedar.

Appearance

The beauty of your new feeders comes from within. A Western

Redcedar tree produces many colors of lumber throughout its diameter.

The sapwood (outer layer of the tree) is typically pure white to mellow

yellow. The closer to the center of the tree, the darker the

wood. Heartwood (the very center of the tree) is

typically dark brown to near black.

Coloring of of your new Hurley-Byrd feeder will

range from glowing gold to pinkish red, or chocolate brown and

may contain multi-colored stripes or beautiful black streaking.

It matters little which part of the tree we use, each and

every Hurley-Byrd feeder is gorgeous in its own right.

Lets take a closer look.

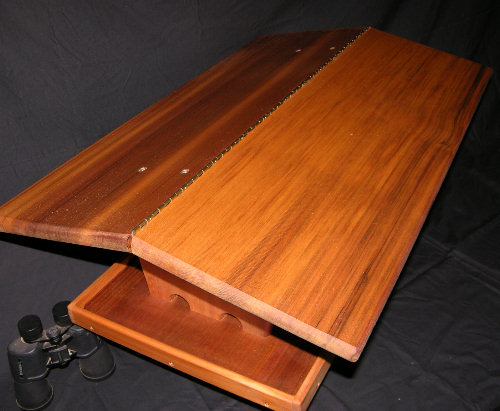

See the photo to the right, which was taken prior to applying

our Penetrating Oil Finish (a must read to understand the true beauty

of an HB feeder), which darkens and exaggerates the contrasting colors.

We have taken sections from five different boards to illustrate how

different the coloring is in our lumber. The piece at the top is a nice

gold and the bottom one is dark brown. The typical lumber coloring

in our feeders is from one of the three bottom sections. The

middle piece and the second from the bottom show how

a single board can have extreme color variances in

one board while the bottom piece illustrates the

beautiful striped effects that may be found.

How We Use This Lumber

Each piece of lumber is inspected for the following:

Soundness - We make sure each piece of lumber is not cracked,

split, twisted or warped in any way. If a piece of lumber is found defective, which is extremely rare, it is placed aside for use in experimental

items, discarded or becomes a garden stake or fence rail.

Natural Beauty - Like the striped effects noted above, we

look for unusual characteristics in the lumber. When we build your

feeder, we "use" these qualities to enhance the design characteristics

of the feeder being crafted. As an example, we will match and

place the dark, chocolate brown edge of a board toward the

peak of a feeder's roof. This visually enhances the depth of

the feeder as dark colors recede and light colors come

forth in our mind's eye. Hence, producing a feeder

with more stimulating visual depth.

Grain and color patterns are accentuated and placed in

such a way as to add greatly to the feeder's attractiveness. Roof

halves, as shown above, always have the most colorful or beautifully

patterned grains as they are the most viewed aspect of the feeder.

No matter what lumber we use, you will be pleased when

you see a Hurley-Byrd feeder for the first time.

When Shopping for New Wildlife Feeders

Keep these wood facts in mind when shopping for new feeders.

Nearly all wood feeder manufacturers use lesser grades of cedar

such as Eastern White Cedar or worse yet, untreated Pine or other unknown species due to their cheap cost. AND, when you do find

feeders manufacturer from Western Redcedar, they

WILL NOT match the premium grade lumber found in

all Hurley-Byrd feeders and their components.

Furthermore, the feeders shown throughout our website

are of the feeder's design. The lumber coloring will always be

different each and every time. Have no fear though, each

feeder is a true "thing-of-beauty" all unto itself.

There is simply no equal anywhere!

Archived History: 2013 Yellawood

What is Yellawood?

Yellawood is a product produced by Great Southern Wood Preserving, Inc.

Yellawood is a Southern Yellow Pine with the latest in preservative treatment of micronized copper.

In a nutshell, it is pressure treated lumber, like your wood deck or other outdoor treated lumber.

BUT

Hurley-Byrd doesn't use any ole preserved wood lumber (PWL). Our PWL is the top

most grade of lumber we can get our hands on. What most people recognize as pressure treated

lumber is that knotty, greenish, yucky stuff found in the large box retailers.

Our PWL is Premium Grade Lumber with very few knots and has been 100% pressure treated

with micronized copper, not the old nasty arsenic, etc.... Yellawood brand is named after the natural,

yellowish color of the finished board's appearance.

Most all Yellawood lumber is shipped to their retailer as "wet" wood. Wet PWL

is what you will find at the lumber yard, even Yellawood. Hurley-Byrd only wanted the best so we

took it one step further and have purchase Yellawood's Kiln Dried After Treatment (KDAT) lumber.

KDAT goes through the normal process of be preserved and then it's put

through a dry kilning process to stabilize the wood's fibers.

But that's not good enough for Hurley-Byrd. We take it a step further. Summer of 2014, we

built a lumber dry kiln to take our premium PWL and dry it even further. We do so in order to stablize

the lumber further and allow us to get our penetrating oil finish to "penetrate" even deeper.

Yellawood uses only the best of their best lumbers for KDAT. It's an appearance grade

lumber which falls in line with what Hurley-Byrd produces. We build beautiful

products and our Yellawood feeders follow suit.

Why did we add in Yellawood?

Truth be told....... cedar is getting way too expensive and, even more so, very

hard to get. We have been fighting the process for the last few years to acquire

our ultra premium grade of cedar and each year it has become more and more difficult, if

not nearly impossible, to buy the right quantities at a reasonable price.

Hence, Yellawood.

Although Yellwood's KDAT is expensive, it is where we need the price to be in order to

hold our feeder's price points where we want. AND, Yellawood is readily available today,

tomorrow and will be for years to come.

AND.... Yellawood is a far stronger lumber. It's structural integrity far supercedes

cedar and will allow us to build more robust products and expand our product line of feeders into

what we have been wanting them to be for several years.

In a nutshell....... Yellawood is stronger, will last longer and still contains the

beauty all Hurley-Byrd feeders are known to have, although a different sort of beauty.

If you have any questions or concerns regarding our new lumber choice,

call us at 877-363-0199 or email: [email protected]

Exclusively at Hurley Byrd

Forest 2 Finish 2 You (FFY)

In a Nutshell:

Forest = We harvest the trees from the Forest

Finish = We produce the lumber, handcraft the product, apply its Finish

You = We ship these wonderful feeders directly to YOU

2 = HB2 (Hurley Byrd's 2nd 15 Years)

Hence - Forest 2 Finish 2 You - FFY

The Details

What is Forest 2 Finish 2 You?

FFY is taking things to a WHOLE NEW LEVEL.

Hurley Byrd has never done things the easy way and it's why we're a step (many

steps actually) above any other wildlife feeding products manufacturer.

And FFY is taking "not easy" to a whole new level. Here at HB we are

now producing our own lumber from our own tree harvesting operations. As of Winter 2019

we're in the midst of building the whole of this program. We have literally built various pieces

of equipment used in the harvesting and the processing of trees residing on our own

property and the properties of others throughout our area.

Our goal and FFY's appeal will be in the green approach it generates. Logging

everywhere revolves around time and labor costs. Hence, loggers trample the land, cut

and tear everything down and then quickly move onto the next. Even here we

understand it must be this way in the competitive lumber market.

But for Hurley Byrd, we can do it differently.

Since we harvest the tree, produce the lumber, dry the fibers and

craft YOUR feeders from that same tree...... we have the great advantage of spreading

these costs through many operations. We can now slow down the harvest, tread

lightly upon the land and hand pick the most forest positive trees to harvest.

These trees are then brought to our facility and utilized far more

effectively than a normal lumber milling operation could ever do. Since we are

sawing the tree specifically for the production of our own products, we can

manage each and every tree's utilization to the nth degree.

Our production goal is to be into strong operations

for the 2018/19 feeding season has been achieved. As of this month (January 2019)

we are 75% to 80% complete and by Christmas 2019 we will positively be 100%.

Hurley Byrd is now taking wildlife feeding to a whole new level.

There is no other organization who does what we're doing and

there is no other wildlife feeding product manufacturer (nor ever has been) who

crafts feeders (or any other product) to the level of quality like Hurley Byrd.

Look for a mix of Appalachian Mountain lumbers from oak,

maple, cherry, hickory and many others. But what we are really excited about is

the fact we live in the midst of Yellow Poplar country........ and even more specific.......

we live in the mountain region of Poplar country. Highland and lowland Poplar is the same tree

but they don't grow the same. Highland Poplar is a far slower growing tree than lowland and

the lumber it produces is tighter grained, heavier and stronger. Best of all though,

Poplar has a beautiful appearance. It ranges in color from near pure white

to a predominant, pretty variety of greens and occasionally dark

purple, browns and black heartwood. Look for Poplar everything

as it represents Hurley Byrd and the state of WV very well.

We are so excited about what is happening here now

and the future. Our new program is allowing us to bring back feeders we

had to abandon years ago due to the unavailability of lumber sizes and is allowing us

to expand into uncharted territory with products we had only dreamed about.

A new era is born here at Hurley Byrd and we want you to be apart of the whole thing.

Matter of fact...... we could not have gotten here without you, our Customer.

And for that........... YOU are now rewarded with the best of our best.

I Personally Thank You,

Peter Hurley

Owner: Hurley Byrd Wildlife Feeders

If you have any questions or comments regarding our new lumber choice,

call us at 877-363-0199 or email: [email protected]

Author: Peter Hurley - Owner of Hurley Byrd February 6, 2018; Updated October 12, 2018; Updated January 15, 2019

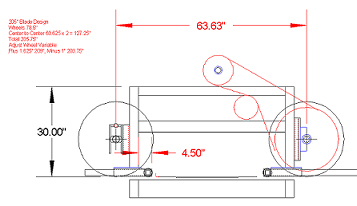

To do this though, we actually needed

to build our own milling equipment. For more than

a few years, I looked at buying various sawmills but

was unable to find exactly what we needed.

Since we predominantly use a

very specific cut of lumber (quartersawn

lumber), there is not a machine which specifically

produces this cut of lumber. So, we sat down

and designed our own.

As of Fall 2018 we have built

an amazing sawmill along with its supporting

equipment and we're targeting the summer

of 2019 to be in full operation.

.

Shop by:

Hurley Byrd's Festival of Feeders

Pick Your Exact Feeder Exclusively on eBay

Hurley-Byrd does it differently: We handcraft every feeder we sell.

Beginning with our own designs, buying and producing the finest materials and crafting your feeders to

near perfection with a beautiful penetrating oil finish so they last for years. We take pride in every step of our service, too.

From the moment you first interact with us, whether on our website or on the phone, to the delivery of

your feeders and gifts and everything in between. We want to make owning and gift giving easy for you.

choose Hurley-Byrd and see what a difference our feeders really make.

All Rights within this web site and its related products are Copyrighted and Reserved by:

Hurley-Byrd, LLC

462 Williams Cross Way

Fairmont, West Virginia 26554

Toll free: 877-363-0199

© 2002 - 2019